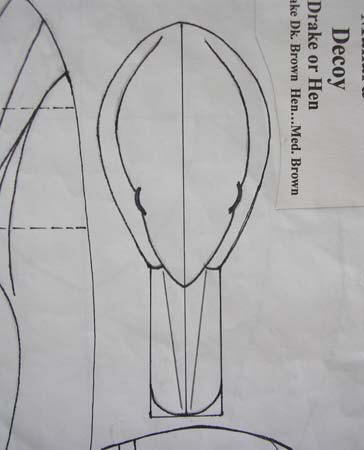

Mallard Head

Carving 101

Starting with a square block of head stock

draw in a center line and locate the top view of the pattern on the

centerline and placing the end of the of the bill at the very end of the

block. Make sure that the block is slightly wider than the widest part

of the top view pattern.

Next locate the eye line

on the top view and using a Square, extend the eye line

down the side of the block. Once this is located place

the side view of the pattern on the side of the block by

aligning the eye on the eye line (push pin) and rotate

the pattern until the end of the bill touches the

outside edge of the block.

Special Note:

This cutout method will only be successful if you are using an accurate

pattern that features matching side and top views. You can usually check

a pattern with a T Square to see if the views match.

Draw around both the top and side views

of the pattern making sure to locate the eye on the side view.

Next using a drill press I locate and

drill the eye hole through the entire block making sure that my drill

press is at a right angle or 90 degrees.

At this point I should reiterate that

it is crucial to make sure you start with a squared block of wood and

your bandsaw and drill press must be set up to cut accurately at a right

angle.

With everything squared up we're ready

for the first cut. With a band saw, cut out the top view first by making

a continuous cut from front to back as seen in the illustration below.

Now its time to cut out the side view

by putting the three pieces back together forming a square block again.

I like to use a touch of hot glue to hold the block together keeping in

mind that a very small drop of glue will do the job. Next cut out the

head side view with the band saw.

Side view cutout

Discard the scrap and you have a head

cutout with two views of the pattern locked in and you are ready to

proceed to locating the carving guidelines.

Start the guidelines by drawing a

center line on the top and bottom of the cutout.

Also draw in the end of the bill shape

on the bottom of the bill. I like to use Vernier Calipers for

transferring measurements from pattern to head. The two points will give

you the same measurement as the distance between the large blades.

Next, referring to your pattern, locate

and draw in the eye channel and cheek lines on the side view of the

cutout. The circle with an X represents the high spot of the cheek or

the widest part of the head which is cheek to cheek.

Next, using the top view of the

pattern, locate and transfer the width of the crown.

Next using the side view of the head

pattern locate and transfer the bill guidelines.

Make special note of the “U” shape at

the lower corner of the bill. It is very easy to locate and transfer

this measurement by putting the points of the Vernier calipers on the

end of the bill and corner of the bill on the pattern and transferring

this measurement to the same area on your head cutout. Repeat for the

top of the bill to locate the horns.

Lastly I establish the round neck

guidelines by drawing a circle and X on the bottom of the neck. The X

helps to get equal parts.

I start the carving process by locking

in the bill. The first cut is at the corner of the bill and I use a half

round gouge to make this cut. You could use a small cylinder cutter if

you are using a power carver to make this cut. The corner of the bill is

now the same width as the rest of the bill and the corner is locked in

place.

Next I lock in the horns of the bill

with a right angle /90 degree cut. A knife or cylinder cutter will work

perfect in this area. Make sure that you do not cut below the horn

guidelines on the side view of the bill otherwise you have cut away the

top of the bill.

Next I continue the right angle cut

using the Eye Channel guideline on the side view and the Crown guideline

on the top view. This cut will lock in the width of the crown. Again it

is very important to make sue that this is a 90 degree cut. See

illustration below.

Finalized Cut

Next step is to start the neck rounding

process by making a groove cut following the illustration. This can be

done with a round rasp, round rotary rasp, or round gouge.

When making this cut remember the final

shape of the neck is round so avoid a flat cut. Guidelines on the neck

bottom will help visualize the proper rounding.

Now it's time to round the neck.

Rounding the crown is the next step.

Round from the centerline on the top of the head down to the eye

channel.

Now you can round from the eye channel

down to the cheek line.

Now you can continue the rounding

process by rounding from the cheek line into the neck area. Remember the

Circle X is the high spot of the cheek or the widest part.

Next is rounding and shaping the bill.

First draw in the shape of the bill on the bottom. The red area will be

removed. Make sure that you are looking at the bottom of the bill when

making the cut and cut with the grain to avoid splitting the bill end.

It's important to note that the widest

part of the Ducks bill is at the bottom and a warning line is located to

preserve the bills shape.

Now we can focus on rounding and final

shape of the top of the bill.

Step 1

Step 2

Step3

Step 4

Step 5

Time to sand the entire head.....It is

now safe to remove your guidelines being careful to just smooth the

surface and remove fuzz and high spots.

Step 6

Once you are finished sanding you can

re-draw in the bill guidelines and you are ready to set the eyes.

Using the pilot hole as a guide open

the eye hole to the proper size either using a half round gouge or an

eye hole drill. Mallard eye size is 10mm.

Make sure you make the hole slightly

larger than glass eye and deep enough to allow for setting the eye to

the proper depth. Fill the eye socket with either Plasticwood or Apoxie

Sculpt and press in the glass eye. Eyes should be set deep enough so the

they are not “bug-eyed” or sticking on the outside of the head. Some of

the Plasticwood or Apoxie will ooze around the eye and can be smoothed

out with a small flat brush. If you are using plastic wood use acetone

to smooth out, and water if you are using the Apoxie.

At this point you can

sand around the eye being very careful not to hit the

glass eye as it will scratch.

Next, it's time to delineate the bill

guidelines. To do this you can use a variety of tools as demonstrated in

the pictures below...

Make a "V" cut using a hook blade and

then sand back into the bill leaving defining the separation of bill and

head feathers. This will leave the feather area higher than the bill.

That edge can also be rounded over to the bill if you prefer a tighter

look.

The same procedure can be done with

power tools also. I prefer using a small cylinder shape diamond cutter

for this task. As stated above the object is to delineate the separation

and then sand smooth back into the bill.

Some carvers like to use a woodburner

for this task. Simply trace the line with the burning pen which defines

the two areas. This is a simple way to go and makes painting easier.

Even simpler is to just paint in the bill without any delineation.

Remember this is a head for a hunting decoy and the incoming waterfowl

will not know which method you used but they will be impressed with your

head shape.

I suggest carving several heads in

order to solidify the carving process and learn the various steps. Once

you feel you have mastered the steps then you can apply the steps to

other species. Questions regarding this demo or various tools used can

be answered by contacting The Duck Blind at 1-800-852-7352 or email

duckblind@mei.net.

Click below to continue

to...

Mallard Body Carving

Tutorial

Mallard Painting Tutorial

Cyber Classroom

Tutorial List

Willy

McDonald